Reliability IAOM 2017

How is reliability defined? Most people expect that; equipment will start and continue to operate as long as needed. But how is Reliability defined? Reliability for equipment is defined as; “the ability to perform a required function under stated conditions for a specific period of time.” An important note: Reliability is not just a maintenance issue, it is a culture. Reliability involves management, maintenance, operations, engineering and all parts of the company.

Learn More

Maintenance programs, are they a costly expense or as an income opportunity? Maintenance cost is almost always treated as an expense. Utilizing reliability maintenance can turn this thinking around and our maintenance programs can begin to create opportunities to increase profits. Most current maintenance programs are typically reactive to failure and attempt to maintain equipment almost exclusively through lubrication. Few alternatives have been utilized to assist equipment in running reliably or efficiently; therefore, reducing the cost of doing business. With a few additions and alterations of maintenance practices, systems can begin to be seen as income instead of expense. Reliability maintenance is a required component of a world class maintenance program and is changing the way maintenance is viewed.

Learn More

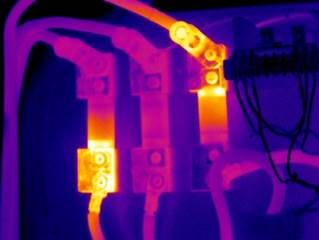

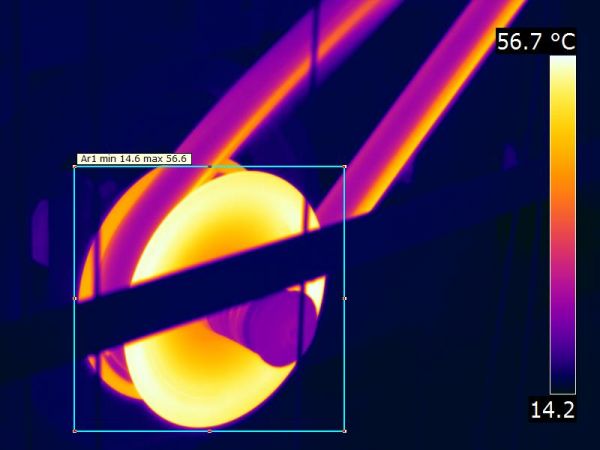

In the ever-expanding field of predictive maintenance, there are technologies and equipment used for non-destructive testing. Within that field, there is a certification available which recognizes the visual skills needed for observing, analyzing and responding to the conditions found within any machine or system and its components. It is these skills that we use in the inspections we conduct. At Pepper Maintenance, we use infrared technologies and/or vibration analysis for predictive maintenance purposes.

Learn More

Reliability Centered (Based) Maintenance in any industry is an approach to plant operations and functions that enable the best profit return and result in bonus, trickle-down effects—improving safety, equipment life, employee comfort, reduced operating costs and greater efficiency—just to name a few. It is a new way of doing business and the returns are great. With a two to five year start-up plan for implementation, and the understanding and cooperation of management and accounting, the success profile will be obvious. Both large and small companies have recognized and acknowledged the value of return to investment.

Learn More

This resource is meant to guide the steps to consistent, reliable data. The purpose of vibration analysis is to reach maximum equipment life, prevent failure and recommend repairs and corrective actions. Machine notes will be kept with the data within the vibration signature.

Learn More

Pepper Maintenance Systems, Inc was founded in 1998 by Randall Springer and Keith Schmidtgall. Randy had worked in the grain industry through farming and in grain elevators. Keith owned an industrial electrical company that had serviced the grain industry for many years. Their goal at the time was to bring infrared inspection services to an industry with great need. Over the years, Pepper Maintenance® has grown from an infrared provider into a full-service reliability company. The team focusses on grain related industries such as elevators, feed mills and flour mills as their primary clientele.

Learn More